Is the flexible packaging in your hand eco-friendly? Adhesive for solvent-free flexible packaging

【More article:What do you know about the food packaging of chips?】

【More article:High-Temperature Retort Pouch-Heat Tolerance Up to 135℃】

.jpg)

The advantages of adhesive for solvent-free flexible packaging

1. It doesn’t cause environmental pollution

Because the adhesive itself is a solvent-free adhesive, there is no solvent volatilized during the process, so it wouldn’t pollute the environment.

2. Lower the energy usage.

During the making process, there is no need for drying equipment to dry the solvent.

3. Erase the erosion of the solvent to printing ink.

Generally, the ink would be affected by the solvent and have a harmful effect. The solvent-free adhesive wouldn’t affect the function of ink.

4. Reduce the cost.

The amount of glue of adhesive for solvent-free flexible packaging is less than the solvent adhesive to reduce the cost.

5. Having a stable finished product.

To allow the finished product to steady, it would erase the effect of high temperature and solvent.

6. Apply small space to process.

The equipment is simple, and the space it used is much smaller than solvent adhesive.

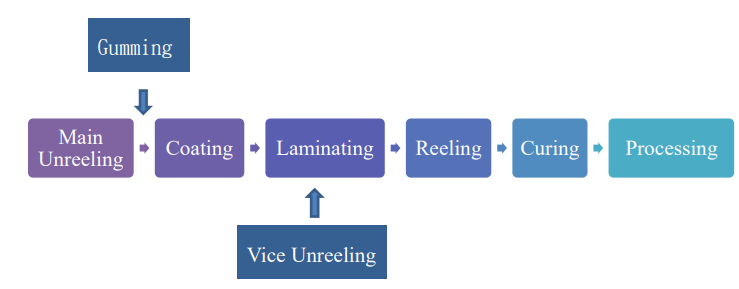

The solvent-free laminating craft process

There are six steps of the solvent-free laminating craft process, which are:1. Unreeling

Under a certain tension, expend the substrates to laminate and gum. Substrates can be two-level, which are main substrate and vice substrate, and the relevant unreeling processes are main unreeling and vice unreeling.

2. Gumming

At a fixed temperature, mix the adhesive in a certain ratio, and transfer it to the laminating machine where it stores glue.

3. Coating

On the basis of the laminating machine structure and product requirement, we evenly coat the adhesive on the substrate.

4. Laminating

On the certain and even pressure, we laminate the main substrate with the vice substrate.

5. Reeling

Reeling the laminating film with a certain tension and reeling pressure.

6. Curing

Put the laminating product in the environment at a certain temperature, and let the adhesive reach expect laminating fastness. Curing is the most important process in the solvent-free laminating craft process; it usually takes a longer time to finish.

The solvent-free laminating craft process common problems and solutions

During the process, there are two common problems, which are white dots and phenomenon and bubble phenomenon. The contents below are the common problems and corresponding solutions.1. White dots

When the compound process ends, you can see different sizes of white dots on the products; this is called the white dots phenomenon. This phenomenon usually appears on the full version of a white background or light color background, because white or light color has worse hiding power.

|

Number |

Cause | Solution |

|---|---|---|

| 1 |

Because the viscosity is too high, causing the top level of ink has a bad cover effect. |

Choosing low viscosity solvent-free type to compound, or lowering the viscosity of glue through process conditions. |

|

2 |

The hiding power of ink is not enough so the white dots problem is clearer than before. |

Raising the hiding power of ink. |

|

3 |

The pressure is not enough to affect the process, and there are white dots in this area. |

Adjusting the process conditions to not appear the white dots at the end of the process. |

2. Bubbles

|

Number |

Cause | Solution |

|---|---|---|

| 1 |

There is too much-left adhesive on the printing film, so there will have bubbles during the volatilization. |

Controlling the solvent on the printing film in a certain range. |

|

2 |

There has not enough surface tension so the glue would be uneven, and there will have bubbles in this area. |

Controlling the surface tension in a certain range. |

|

3 |

There is not enough glue, causing a big area of the bubble because the glue is not even. |

Adding certain amount of glue. |

Solvent-free PUA (Polyurethane Adhesive for Flexible Packaging Lamination)

Solvent-free adhesive is eco-friendly adhesive, it doesn’t emit the VOCs during the process. Also, it has the advantages of low cost, low energy waste, laminating speed is fast, and level of automation is high.|

Component A |

Viscosity (CPS/25℃) |

Component B |

Viscosity (CPS/25℃) |

|---|---|---|---|

|

1500-4000 |

3000-5500 | ||

| 2500-4500 | |||

| 1500-4500 | |||

| 4000-7000 |

|

Component A |

Component B |

Plastic//Plastic |

Aluminum Metalized Film |

Aluminum//Plastic | Retort Type(Intermediate Temperature) | Retort Type (High Temperature) |

|---|---|---|---|---|---|---|

|

V |

V |

V | V | V | ||

|

V |

V |

V | V | V | ||

| FA-876AH | FA-276BH | V | V | V | V | V |

| FA-825A | FA-225B | V | V |

Flexible packaging is not a surprise when it appears in our daily life, so using eco-friendly adhesive is an important thing. Coating P. Materials provides adhesive for solvent-free flexible packaging that has the advantages of higher initial adhesion, soft and transparent, which can provide the customers a perfect and strong flexible packaging, at the same time protecting the environment of the earth together. If you want to know more about the product information, please contact us.