News & Events

What do you know about the food packaging of chips?

February 23,2022

A relaxing pattern everyone is familiar with is that when you comfortably lying on the couch, at the same time watching the movie with a bag of chips. However, do you know the food packaging of chips? The food packaging with chips is called flexible packaging. It’s mainly used flexible materials, such as paper, film, aluminum, and metalized film. Have you ever thought of what composed the flexible packaging of chips? Why every flexible packaging can print colorful images that would attract you to buy it? In this article, we will parse the construction of flexible packaging.

.jpg)

The advantages of flexible packaging

【More Article: Circular economy is all the rage - The indispensable flexible packaging lamination trend】

Flexible packaging constantly appears in people’s life. You can see different kinds of flexible packaging with patterns and colors as long as you walk into one convenience store. Flexible packaging has many advantages, these advantages are also the reason it can be applied in different businesses, such as food, electronic, aesthetic medicine, chemistry, and industrial materials industry.

1. It can satisfy the protection of products diversities, and prolong the durability period.

Flexible packaging can be combined with different materials, each material has its characteristic to protect the products and prolong the durability period. These materials usually can satisfy the requirements of blocking steam, gas, fat, oil solvent, or rust protection, electromagnetic radiation protection, statics protection, chemical resistance, aseptic preservation, and free from toxic and contamination.

2. It can be simply made, operated, and convenient to use.

When producing flexible packaging, you can just purchase high-quality machines to produce a huge amount of flexible packaging. The technique is easy to control. For customers, flexible packaging is convenient to use and easy to open.

3. Especially suitable for marketing, and have the stronger attraction of products.

Flexible packaging can be seen as the friendliest way of packaging because its construction is light and comfortable to touch. The characteristic of color printing makes it industry easy to express the product message and specialty completely, to attract customers to purchase the products.

4. Low cost of packaging and transportation

The flexible packaging is constructed with film, so the space that packaging materials take is small. Transportation is very easy, the overall cost compared with the hard packaging is substantially decreased.

The characteristics of 7 kinds flexible packaging printing substrate.

Each flexible packaging usually has different kinds of patterns and colors to attract customers to purchase. Flexible packaging printing can be divided into three ways, which are surface printing, reverse printing and reverse printing with compound packaging. Surface printing is the ink printing on the top surface of the packaging. Reverse printing is patterns printing on the inner layer of packaging, and would be contacted with the food. As for reverse printing with compound packaging, it’s using compound packaging and reverses printing on the top layer. There are 7 kinds of printing substrates, each kind has its unique characteristic, and is suitable for different kinds of flexible packaging to use.

1. BOPP

It’s the most normal flexible packaging printing substrate. During the printing, there cannot have small holes, or it would affect the printing quality. Pay attention to thermal contraction, surface tension, and surface smoothness. The printing tension needs to be controlled and the dry temperature needs to be lower than 80℃.

2. BOPET

Because the PET film usually is thinner, printing needs to have bigger tension to produce. BOPET only uses certain ink, so it’s better to use professional ink. Using the normal ink would let the content easily separate. When printing, the printing room should keep the same humidity, it can help to endure a higher dry temperature.

3. BOPA

The specialty is easily absorbed wet and transformed to another shape, so we need to be careful with this key factor when printing. Because it easily absorbs wet and transforms to another shape, it needs to be used immediately, and the rest of the film should wrap with moisture-proof packaging. The BOPA film that is already printed should go to the next process. If it cannot immediately process, it needs to be sealed and the normal store time would not exceed 24 hours.

4. PVDC

The uniformity is not good, and the surface is not even. The PVDC is hard and crispy, so the printing pressure and tension cannot be too large. It’s hard to overprint, and only can use a certain solvent. If you use the wrong solvent, it would melt the coating. The solvent residue is large and easy to stick, so be careful with the drying and cooling.

5. MATOPP

It can be used OPP process to do reserve printing. The surface of MATOPP cannot endure high temperatures, so it needs to control dry temperature.

6. PL

The printing would use surface printing and would choose the surface printing ink with better transparency. When processing the printing, it needs to use a lower dry temperature and select the professional thermal contraction ink. Make sure the ink would not separate when the film is processing thermal contraction.

7. CPP、CPE

The unstretched PP and PE films have low printing tension, and it’s also hard to overprint. When designing the patterns, we need to be concerned about the deformation of patterns.

The construction of flexible packaging

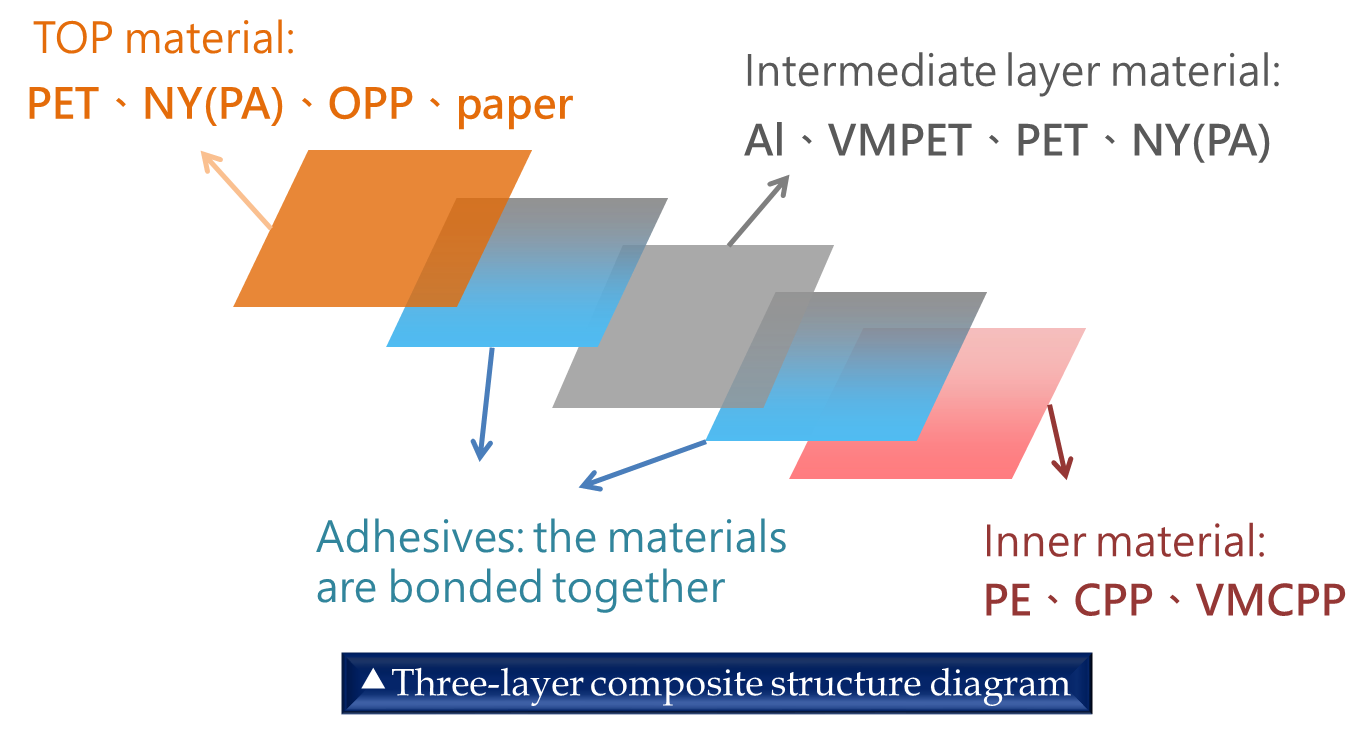

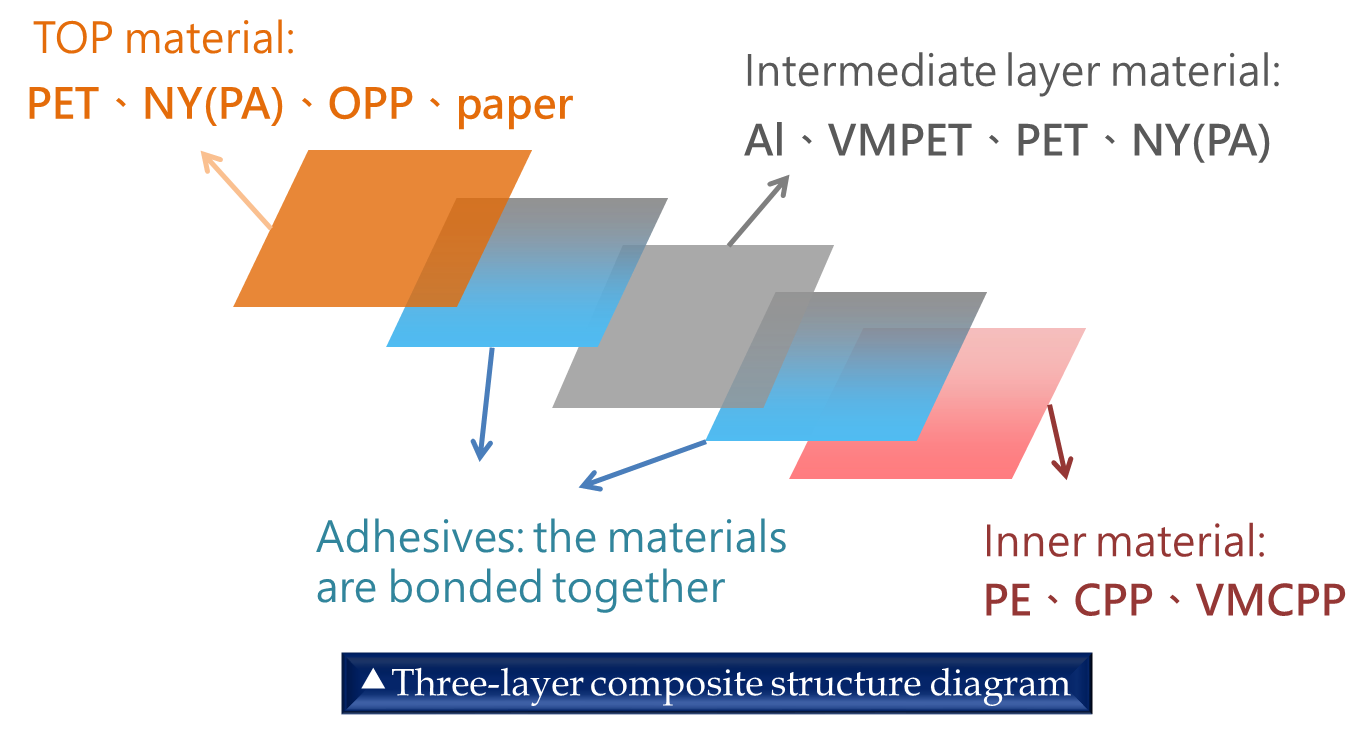

As the name suggests, the flexible packaging material is composed of different layers of materials. From the simple construction perspective, we can divide flexible packaging into three layers. The top material usually would be PET, NY (PA), OPP or paper. The intermediate layer material would be Al, VMPET, PET or NY (PA). The inner material would be PE, CPP or VMCPP. Applying the adhesive between top material, intermediate layer material, and inner material, let these three layers combine.

PUA (Polyurethane Adhesive for Flexible Packaging Lamination)

As mentioned, each layer of flexible packaging has adhesive. The PUA (Polyurethane Adhesive for Flexible Packaging Lamination) that Coating P. Materials provide can be divided into solvent-free type adhesive and general type adhesive.

1. Solvent-free type 【More product information】

The solvent-free adhesive is eco-friendly adhesive. During the process, there is no VOCs emission. At the same time, the advantages are the low cost, complex velocity fast, automation degree high, and low energy cost.

(Chart 1/Coating PUA solvent-free type product information)

(Chart 2/Coating PUA solvent-free type product characteristic)

2. General type 【More product information】

The general type adhesive has the advantages of transparency, flexibility, and heat resistant. It has higher initial adhesion, and possesses higher peel strength for aluminum-plastic packaging products.

(Chart 3/Coating PUA general type product information)

(Chart 4/Coating PUA general type product characteristic)

In our daily life, many things need adhesives. However, we seldom realize the existence of these adhesives. Same as the flexible packaging, it uses adhesive to combine different layers of film. Take the color painting factory as an example, they understand the construction of different layers and adhesive of flexible packaging. The surface of flexible packaging needs rich patterns and colors to attract customers to purchase. During the printing process, the color painting factory would print the pattern on a layer of film, and use the adhesive to combine the film with pattern to other layers of films. Coating P. Materials provides the PUA (Polyurethane Adhesive for Flexible Packaging Lamination) with great lamination to many kinds of films. It does not affect the printing quality of ink and has the advantages of high initial adhesion and heat resistance. If you want to know more about product information, welcome to contact us.

.jpg)

(Image: piqsels)

The advantages of flexible packaging

【More Article: Circular economy is all the rage - The indispensable flexible packaging lamination trend】

Flexible packaging constantly appears in people’s life. You can see different kinds of flexible packaging with patterns and colors as long as you walk into one convenience store. Flexible packaging has many advantages, these advantages are also the reason it can be applied in different businesses, such as food, electronic, aesthetic medicine, chemistry, and industrial materials industry.

1. It can satisfy the protection of products diversities, and prolong the durability period.

Flexible packaging can be combined with different materials, each material has its characteristic to protect the products and prolong the durability period. These materials usually can satisfy the requirements of blocking steam, gas, fat, oil solvent, or rust protection, electromagnetic radiation protection, statics protection, chemical resistance, aseptic preservation, and free from toxic and contamination.

2. It can be simply made, operated, and convenient to use.

When producing flexible packaging, you can just purchase high-quality machines to produce a huge amount of flexible packaging. The technique is easy to control. For customers, flexible packaging is convenient to use and easy to open.

3. Especially suitable for marketing, and have the stronger attraction of products.

Flexible packaging can be seen as the friendliest way of packaging because its construction is light and comfortable to touch. The characteristic of color printing makes it industry easy to express the product message and specialty completely, to attract customers to purchase the products.

4. Low cost of packaging and transportation

The flexible packaging is constructed with film, so the space that packaging materials take is small. Transportation is very easy, the overall cost compared with the hard packaging is substantially decreased.

The characteristics of 7 kinds flexible packaging printing substrate.

Each flexible packaging usually has different kinds of patterns and colors to attract customers to purchase. Flexible packaging printing can be divided into three ways, which are surface printing, reverse printing and reverse printing with compound packaging. Surface printing is the ink printing on the top surface of the packaging. Reverse printing is patterns printing on the inner layer of packaging, and would be contacted with the food. As for reverse printing with compound packaging, it’s using compound packaging and reverses printing on the top layer. There are 7 kinds of printing substrates, each kind has its unique characteristic, and is suitable for different kinds of flexible packaging to use.

1. BOPP

It’s the most normal flexible packaging printing substrate. During the printing, there cannot have small holes, or it would affect the printing quality. Pay attention to thermal contraction, surface tension, and surface smoothness. The printing tension needs to be controlled and the dry temperature needs to be lower than 80℃.

2. BOPET

Because the PET film usually is thinner, printing needs to have bigger tension to produce. BOPET only uses certain ink, so it’s better to use professional ink. Using the normal ink would let the content easily separate. When printing, the printing room should keep the same humidity, it can help to endure a higher dry temperature.

3. BOPA

The specialty is easily absorbed wet and transformed to another shape, so we need to be careful with this key factor when printing. Because it easily absorbs wet and transforms to another shape, it needs to be used immediately, and the rest of the film should wrap with moisture-proof packaging. The BOPA film that is already printed should go to the next process. If it cannot immediately process, it needs to be sealed and the normal store time would not exceed 24 hours.

4. PVDC

The uniformity is not good, and the surface is not even. The PVDC is hard and crispy, so the printing pressure and tension cannot be too large. It’s hard to overprint, and only can use a certain solvent. If you use the wrong solvent, it would melt the coating. The solvent residue is large and easy to stick, so be careful with the drying and cooling.

5. MATOPP

It can be used OPP process to do reserve printing. The surface of MATOPP cannot endure high temperatures, so it needs to control dry temperature.

6. PL

The printing would use surface printing and would choose the surface printing ink with better transparency. When processing the printing, it needs to use a lower dry temperature and select the professional thermal contraction ink. Make sure the ink would not separate when the film is processing thermal contraction.

7. CPP、CPE

The unstretched PP and PE films have low printing tension, and it’s also hard to overprint. When designing the patterns, we need to be concerned about the deformation of patterns.

The construction of flexible packaging

As the name suggests, the flexible packaging material is composed of different layers of materials. From the simple construction perspective, we can divide flexible packaging into three layers. The top material usually would be PET, NY (PA), OPP or paper. The intermediate layer material would be Al, VMPET, PET or NY (PA). The inner material would be PE, CPP or VMCPP. Applying the adhesive between top material, intermediate layer material, and inner material, let these three layers combine.

(Image: Coating P. Materials)

PUA (Polyurethane Adhesive for Flexible Packaging Lamination)

As mentioned, each layer of flexible packaging has adhesive. The PUA (Polyurethane Adhesive for Flexible Packaging Lamination) that Coating P. Materials provide can be divided into solvent-free type adhesive and general type adhesive.

1. Solvent-free type 【More product information】

The solvent-free adhesive is eco-friendly adhesive. During the process, there is no VOCs emission. At the same time, the advantages are the low cost, complex velocity fast, automation degree high, and low energy cost.

| Component A | Viscosity | Component B | Viscosity |

| FA-818A | 2000-4000 | FA-218B | 400-700 |

| FA-818AF | 2000-4000 | FA-218BF | 2500-4500 |

| FA-825A | 3000-5000 | FA-225B | 4000-7000 |

| FA-876A | 2000-4000 | FA-276B | 2500-4500 |

| FA-876AH | 2500-5000 | FA-276BH | 1500-4500 |

|

Component A |

Component B |

Plastic//Plastic |

Aluminum Metalized Film |

Aluminum//Plastic |

Retort Type (Intermediate Temperature) |

Retort Type (High Temperature) |

|---|---|---|---|---|---|---|

| FA-818A | FA-218B | V | V | |||

| FA-818AF | FA-218BF | V | V | V | V | |

| FA-876A | FA-276B | V | V | V | V | V |

| FA-876AH | FA-276BH | V | V | V | V | V |

| FA-825A | FA-225B | V | V |

2. General type 【More product information】

The general type adhesive has the advantages of transparency, flexibility, and heat resistant. It has higher initial adhesion, and possesses higher peel strength for aluminum-plastic packaging products.

| Component A | Viscosity | Solid Content | Component B | Viscosity | Solid Content | Solvent |

| CX-2022 | 1000-5000 | 62±2 | CA-875LT | 500-2500 | 75±2 | EAC |

| CX-2068 | 3500-6600 | 70±2 | CA-880LT | 1000-4200 | 80±2 | EAC |

| CX-2070 | 3500-7500 | 70±2 | CA-885LT | 4000-8500 | 80±2 | EAC |

| CX-2072 | 4000-6500 | 70±2 | CA-800D | 2000-8000 | 76±3 | EAC |

| CX-2270 | 1000-3000 | 62±2 | CA-775LT | 1000-3000 | 76±3 | EAC |

| CX-2522 | 1800-2800 | 62±2 | CA-775LT | 1000-3000 | 76±3 | EAC |

| CX-2550 | 1000-3800 | 50±2 | CA-775LT | 1000-3000 | 76±3 | EAC |

| CX-2570 | 600-1500 | 70±2 | CA-775LT | 1000-3000 | 76±3 | EAC |

| CX-2750 | 1000-3000 | 50±2 | CA-775LT | 1000-3000 | 76±3 | EAC |

| Component A | Component B | Plastic//Plastic | Aluminum Metalized Film | Aluminum//Plastic | Retort Type (Intermediate Temperature) | Retort Type (High Temperature) |

| CX-2022 | CA-875LT | V | V | V | ||

| CX-2068 | CA-880LT | V | V | |||

| CX-2070 | CA-885LT | V | V | V | ||

| CX-2072 | CA-800D | V | V | |||

| CX-2270 | CA-775LT | V | V | V | ||

| CX-2522 | CA-775LT | V | V | V | V | V |

| CX-2550 | CA-775LT | V | V | V | V | V |

| CX-2570 | CA-775LT | V | V | V | V | V |

| CX-2750 | CA-775LT | V | V | V | V | V |

In our daily life, many things need adhesives. However, we seldom realize the existence of these adhesives. Same as the flexible packaging, it uses adhesive to combine different layers of film. Take the color painting factory as an example, they understand the construction of different layers and adhesive of flexible packaging. The surface of flexible packaging needs rich patterns and colors to attract customers to purchase. During the printing process, the color painting factory would print the pattern on a layer of film, and use the adhesive to combine the film with pattern to other layers of films. Coating P. Materials provides the PUA (Polyurethane Adhesive for Flexible Packaging Lamination) with great lamination to many kinds of films. It does not affect the printing quality of ink and has the advantages of high initial adhesion and heat resistance. If you want to know more about product information, welcome to contact us.