- Products

- Thermoplastic Polyurethane

- Polyester Type

Polyester Type

TPU extrusion series are commonly applied to extrusion products.

They have many characteristic as follow,

+ Excellent abrasion resistance

+ Good temperature resistance

+ Slice resistance

+ Tear resistance

+ Break-stretching resistance

+ Easy to process

+ Light and transparent

+ Practical and pleasing to the eyes

PRODUCT DESCRIPTION

- Good workability, good fluidity, good transparency

APPLICATION TO END-USE PRODUCTS

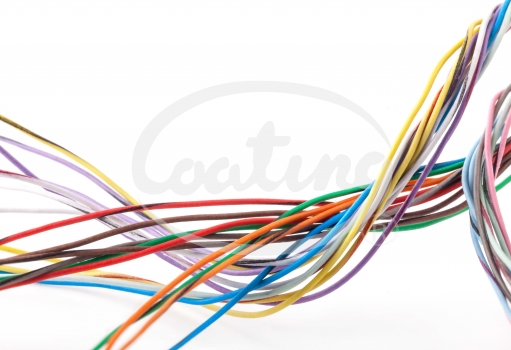

- General extrusion type coiled tube, linear tube, braided hose, screw

- Cover on steel wire, wire & cable, profile extrusion

PRODUCTS

ADD Inquiry| INQUIRY | Property (Test Method) |

Hardness (Shore A/D) (ASTM D2240) |

100% Modulus (Kgf/cm²) (ASTM D412) |

300% Modulus (Kgf/cm²) (ASTM D412) |

Tensile Strength (Kgf/cm²) (ASTM D412) |

Ultimate Elongation (%) (ASTM D412) |

|---|---|---|---|---|---|---|

| EB-85AR1 | 85±2A | 85 | 150 | 330 | 380 | |

| EB-85AD | 85±2A | 70 | 120 | 190 | 400 | |

| EB-90A | 90±2A | 100 | 230 | 300 | 320 | |

| EB-92AD | 92±2A | 100 | 200 | 300 | 350 | |

| EB-95A | 95±2A | 130 | 280 | 340 | 350 | |

| EB-98A | 98±2A | 170 | 300 | 380 | 350 | |

| EB-98A3 | 98±2A | 140 | 280 | 360 | 400 | |

| EB-98AH | 54±2D | 180 | 385 | 490 | 500 | |

| EX-75AW | 76±2A | 50 | 90 | 300 | 700 | |

| EX-80A | 80±2A | 50 | 85 | 300 | 800 | |

| EX-85A | 85±2A | 65 | 90 | 230 | 600 | |

| EX-85AY | 85±2A | 60 | 90 | 300 | 700 | |

| EX-90A | 90±2A | 70 | 110 | 320 | 550 | |

| EX-95A | 95±2A | 110 | 170 | 340 | 450 | |

| EX-95AUL | 95±2A | 100 | 300 | 400 | 450 | |

| EX-98A | 98±2A | 140 | 200 | 380 | 400 | |

| EX-62D | 62±2D | 215 | 330 | 330 | 300 | |

| TB-87AUN | 87±2A | 50 | 80 | 260 | 620 | |

| EX-95AMU | 93±2A | 127 | 200 | 270 | 540 | |

| EX-75AE | 75±2A | 30 | 40 | 190 | 1,000 | |

| NB-80D | 77.5±2.5A | 500 | - | 675 | 150 |

REMARKS

- We can provide unique products according to each customer's requirement beyond the above categories.

- The data is for reference because it changes according to different designs made by customers.