The key to eco-friendly textile laminating- PUD (water-based polyurethane dispersions)

【More Article:Textile coatings go green- the application of waterborne polyurethane dispersions】

The common application of textile

The application of textile can be divided into three categories, which are clothing textile, decorating textile, and industrial textile.

1. Clothing textile:

Same as the clothes we wear every day; it has the functions of practical, comfortable, and sanitation. There are also have clothing textiles that can respond to special environmental changes, so they have the functions of waterproof, flame-retarding, heat resistance, heat insulation, and pressure resistance.

2. Decorating textile:

As for decorating textile, normally it would require the function of flame-retarding. It usually applies to the sofa, furniture, curtain, or artwork.

3. Industrial textile::

It can be separated as direct using and compound using. Direct using means we can use the textile in the product, compound using means the textile needs to be corporate with other materials. Direct using products are absorbent gauze, parachute, and tent. Compound using products are conveyor belts and rubber shoes.

The categories of fibers

The definition of textile product is using different kinds of fibers and processing with different methods. The fiber also has several kinds of categories. Fiber can be divided into natural fiber and artificial fiber. The advantages of natural fiber are warm and soft, the disadvantages are the life of the fabric can’t last long, and it is easy to deform. The method of identifying natural fiber and artificial fiber is to burn them with fire. There will be the smell of feathers burning after the natural fiber is burned, the result would be like powder. On the other hand, there will be the smell of bibulous paper burning after the artificial fiber burns, and the result would be a curly shape in the tail of the fiber..jpg)

(Image:piqsels)

The basic elements of textile laminating

To meet the customers’ needs for the textile function, the fabric normally would laminate with different kinds of materials. Textile laminating can be divided into the fabric to fabric or fabric to film. Normally we would use the fabric to film, such as the clothes that have the function of waterproof are made of fabric to film. The basic elements of textile laminating are substrate, the fabric or film that laminate with the textile, laminator, and adhesive. The substrate can be fabric, film, or leather, and the film that laminates with the substrate can be divided into hydrophilic film and microporous film.

The introduction of PUD (water-based polyurethane dispersions)

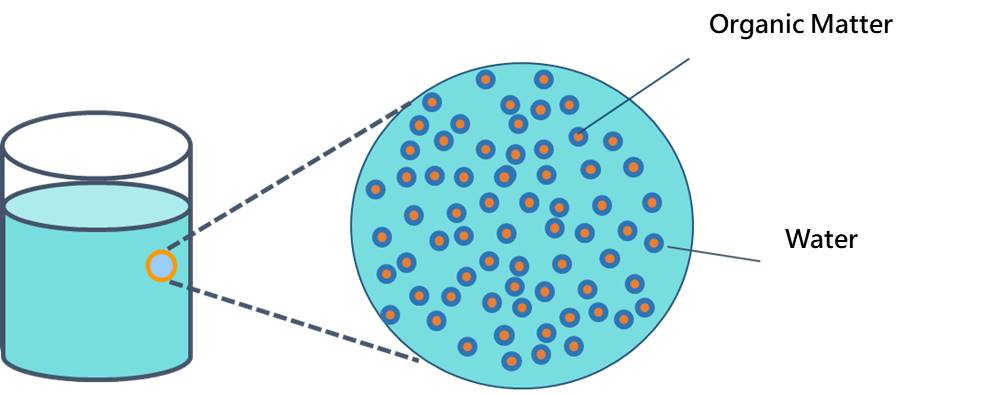

In the past, we usually use solvent polyurethane adhesive, and there would produce a huge amount of VOCs during the process to danger human health. To corporate the public attention to eco-friendly, there are fewer people using solvent polyurethane adhesive and changing to PUD (water-based polyurethane dispersions). PUD (water-based polyurethane dispersions) is mainly using water as a solvent, normally called polyurethane dispersion. From the simple aspect, PUD is the combination of polyurethane and water, which is a kind of material that evenly disperses organic matter.

(Image: Coating P. Materials-PUD organic matte evenly dispersed)

The characteristics of PUD (water-based polyurethane dispersions)

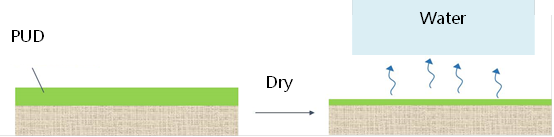

There are three environmental characteristics of PUD: one is the PUD uses water as the dispersion medium, so the process doesn’t need the organic solvent and will not have the problem of VOCs emission (As the image below). Second, the PUD is relatively low toxic, so there will no health danger to the producing workers. Third, it raises the safety of storage in the industry, because the PUD itself doesn’t have the ability of explosive and non-flammable.

(Image: Coating P. Materials-PUD dry and volatilize)

PUD (water-based polyurethane dispersions)

PUD (water-based polyurethane dispersions) has two kinds of using categories, which are adhesive and coating. Below is the specific product information of PUD.

1. Adhesive (More product information)

|

Item |

Solid Content |

Viscosity |

100% Modulus |

Application |

|---|---|---|---|---|

|

WD-6010 |

50±2 |

100-6000 |

<10 |

Lamination between cloth and OPP, CPP, VMCPP, VMPET, NY and other non-polar substrate. |

|

WD-6011 |

45±2 |

10-8000 |

Soft polyether adhesive | |

| WD-6030 | 30±2 | <1000 | 70-90 | Lamination between PVC sheet and mesh fabric |

| WD-6045 | 40±2 | 100-3000 | <10 | Soft polyether adhesive for the lamination of PU film and fabric. |

| WD-6046 | 45±2 | 100-6000 | ≤10 | Soft polyether adhesive , high tack, lamination between TPU film and PUD surface layer. |

| WD-6046W | 45±2 | 100-6000 | ≤10 | Soft polyether adhesive , high tack, lamination between TPU film and PUD surface layer. |

| WD-6054 | 50±2 | 100-8000 | 60-90 | Hydrolysis and hot melt adhesive |

| WD-6058 | 50±2 | <6000 | 60-90 | Suitable for rubber shoes and high solid content |

| WD-6065 | 45±2 | 200-8000 | 20-40 | Middle soft adhesive for the lamination of PVC film and fabric |

2. Coating (More product information)

|

Item |

Solid Content |

Viscosity |

100% Modulus |

Application |

|---|---|---|---|---|

|

WD-1011 |

43±2 |

100-4000 | 10-30 | Suitable for elastic fabric coating and printing ink, which gives products good hydrolysis resistance. |

|

WD-1021 |

30±2 | <1500 | 15-35 | Suitable for elastic fabric coating and printing ink, which gives products good hydrolysis resistance. |

| WD-1021S | 30±2 | <1500 | 5-25 | Top layer application, suitable for elastic fabric coating and printing ink. |

| WD-1030 | 40±2 | 10-4000 | 20-40 | Soft top layer application, flexion resistance, solvent resistance and yellowing resistance. |

| WD-1045 | 40±2 | <4000 | 45-65 | Middle soft top layer application, scratch and abrasion resistance, flexion resistance, hydrolysis resistance, yellowing resistance. |

| WD-1050 | 40±2 | <4000 | 45-65 | Middle soft top layer application, scratch and abrasion resistance, flexion resistance, hydrolysis resistance, solvent resistance and yellowing resistance. |

| WD-1085 | 35±2 | <4000 | 60-85 | Applied to fabric by transfer coating with release paper, scratch resistance, abrasion resistance and yellowing resistance. |

| WD-5035 | 40±2 | <4000 | 10-70 | Applied to top layer of coating, water pressure resistance, flexion resistance, and yellowing resistance. |

| WD-5038 | 30±2 | <4000 | 30-40 | |

| WD-5057 | 50±2 | <6000 | 60-90 | Applied to hard cases, water pressure resistance, flexion resistance and yellowing resistance. |

| WD-5320 | 43±2 | 20-50 | 22-32 | Low viscosity, high solid content, good rebound, gentle and volume feeling. |

PUD (water-based polyurethane dispersions) can be used in many different kinds of industries; one of the industries is textile. Because the solvent is mainly water, there will be no dangerous elements emission during the process. This makes the PUD (water-based polyurethane dispersions) become one of the environmental materials. At the same time, it has the advantages of being non-toxic, solvent-free, and easy to operate, which makes it be used well in every industry. If you want to know more about product information, welcome to contact us.

Reference:

1. 力上西服-布料的纖維種類簡介。檢自 https://lih-shang.com.tw/blog/%E5%B8%83%E6%96%99%E7%9A%84%E7%BA%96%E7%B6%AD%E7%A8%AE%E9%A1%9E%E7%B0%A1%E4%BB%8B/。