Leather without pollution: TPU calendered material brings new momentum to the synthetic leather industry

A、Common leather types and development status

1. Animal leather

The well-known animal leather is usually made of mammalian or reptile hides after tanning. Its surface texture is irregular and full of micro pores, which has air permeability but is also easy to be affected by moisture. Taking the fashion industry as an example, wear-resistant cowhide and precious sheepskin have their followers. However, in recent years, the EU environmental protection organization has clearly advocated non-killing policy and prohibited the sale of animal leather. This has resulted in a gradual imbalance between supply and demand in the animal leather market. Therefore, different alternative materials and production processes have been developed in the artificial / synthetic leather market to fill the demand gap.

2. PVC artificial leather

PVC is a kind of thermoplastic resin with high plasticity and a texture very similar to real leather. PVC was commonly used as raw material of artificial leather in the early days. In order to overcome the disadvantages of impact resistance and poor thermal stability, plasticizer must be added in the production process to meet the basic physical property requirements. It has been proven that long-term exposure to plasticizer will damage the nervous system and urinary system of the human body, which does not comply with international environmental protection trends and regulatory requirements; In addition, PVC will produce dioxin during thermal processing or burning, which not only has the risk of causing cancer, but also interferes with human endocrine. Although PVC can be recycled and reused, it cannot be decomposed by itself in the natural environment, and the released toxic substances will cause long-term harm to the global environment.

▲The international boutique LV tanned PVC and canvas to make a unique leather material, creating classic and timeless fashion pieces.

(Image Source: LOUISVUITTON®)

3. PU synthetic leather

PU synthetic leather is usually based on textile, non-woven or microfiber cloth, and is processed by resin foaming or film covering with different formulations. PU synthetic leather has the advantages of neat edge, higher production and utilization rate than natural leather, relatively affordable price (about 40-50% of natural cattle hides), lightweight, waterproof, and easy to maintain. In recent years, the synthetic leather market advocates a more environmentally friendly water-based PU surface layer to replace animal leather and traditional PVC artificial leather. Technically, it can not only produce the microporous structure almost the same as animal leather, but also simulate smoothness and non-dryness leather feel.

▲Stella McCartney teamed up with adidas Originals to create the first Stan Smith made of polyurethane in 2018.

(Image Source: HYPEBEAST®)

B、Application and solution of TPU elastomer technology in synthetic leather

1. Advantages of TPU material

-

Customization: TPU (Thermoplastic Polyurethane Elastomer) is a high-molecular polymer with physical properties between plastic and rubber. It can be customized according to the demand, and cooperate with different production processes.

-

Easy to process: The processing temperature range is wide, and it can be matched with different types of processes and methods, no need to change the existing equipment.

-

Environmentally friendly: TPU itself is an environmentally friendly material with bio-degradation characteristics, and the finished product can be recycled.

- High-value applications: The superior physical and chemical properties of TPU can actively develop high-value synthetic leather products, such as functional shoes, international boutiques, customized sofas, automotive interiors/parts, professional medical supplies, etc., and become a new driving force for the operation and growth of enterprises.

▲ (Image Source: pexels)

▲ (Image Source: CPMC)

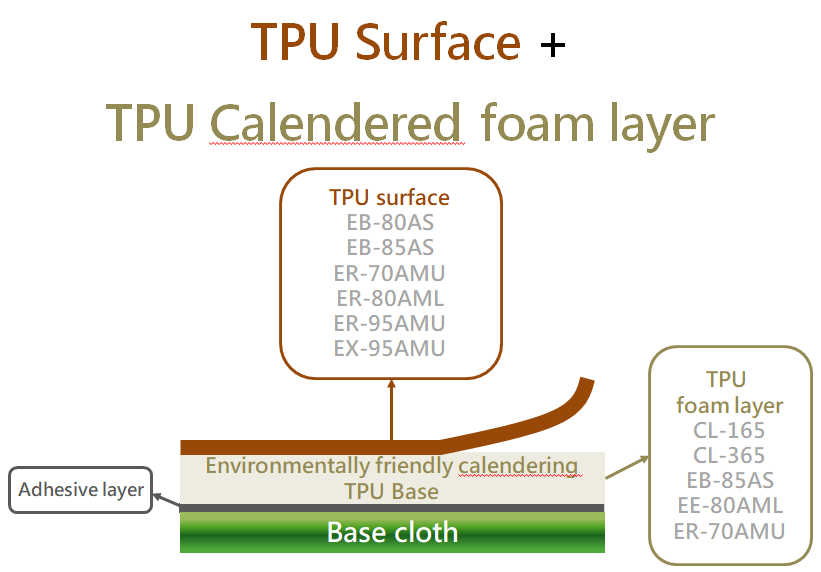

2. Advantages of TPU Calendering Synthetic Leather Process

-

Continuous production process: Calendering is a continuous production process. First, TPU is melted and plasticized, and then the material is rolled into a film of specific thickness. At the same time, the finished product is made by laminating the bottom slot. An embossing roll can also be used to produce different patterns on the surface of the finished product, and finally cooled down and shaped.

-

No re-investment required: The machine used to produce PVC artificial leather can also directly produce TPU calendaring synthetic leather without any additional purchase or modifying production line. CPMC has successfully developed a calendered TPU elastomer with high transparency and no precipitation by adjusting the proportions and parameters of the TPU formula, which solves the problems of roller sticking and excessive load on the production machine.

-

Environmental protection processes: From raw materials, processing to the finished product stage are no emissions of harmful substances, which is friendly to the global environment, does not pose a threat to human health, and conforms to the global environmental protection trend.

- Finished products can replace PVC/PU leather: TPU calendered synthetic leather has similar physical properties as PU synthetic leather, and its softness, abrasion resistance and scratch resistance are better than existing PVC artificial leather. At present, many major international factories are turning to environmentally-friendly TPU calendered synthetic leather to enter the future market layout.

▲ CPMC calendering grade materials have been verified by many calendering plants, and synthetic leather can be produced with existing equipment.

(Image Source: Thai Nam Plastic)

3. CPMC calendered TPU materials and their properties

| Item | Hardness (Shore A/D) |

Modulus, 100% (Kgf/cm²) |

Modulus, 300% (Kgf/cm²) | Tensile Strength (Kgf/cm²) |

Elongation at Break |

| Test Method | ASTM D2240 | ASTM D412 | ASTM D412 | ASTM D412 | ASTM D412 |

| ER-70AMU | 72±2A | 30 | 50 | 150 | 850 |

| ER-80AML | 80±2A | 48 | 80 | 250 | 650 |

| ER-95AMU | 93±2A | 110 | 220 | 250 | 335 |

| EB-80AS | 82±2A | 60 | 130 | 210 | 550 |

| EB-85AS | 85±2A | 70 | 170 | 330 | 500 |

| EX-95AMU | 93±2A | 115 | 250 | 300 | 340 |

▲ CPMC environmental TPU calendered leather solutions.

(Image Source: CPMC)