News & Events

New Option for Textiles Coating, Waterproof and Breathable Fabrics Take Functional Clothing Market Share

October 05,2020

With outdoor sports and workouts on the rise, camping, hiking, and workout areas where can see lots of people enjoying exercise.

The outfit will change with daily life and exercise transformation. Clothing is the human body's second skin, and comfort may impact exercise performance. Therefore, it's very important to purchase functional clothing which can shuttle through different situations. Do you know the usual functions of functional cloth, like waterproof and breathable, windproof & breathable, moisture-transferring, and quick drying, plus cool and dry fast? Do you understand those functions? Big brands roll out new fabrics with different prices and styles; there are all kinds of technical terms and data on tags confusing us. This article will explore the essence of waterproof & breathable fabrics, and the techniques of textiles coating, thus to know the meaning of functional clothing. Make you not only fashionable but also pick out proper products that meet your need.

The outfit will change with daily life and exercise transformation. Clothing is the human body's second skin, and comfort may impact exercise performance. Therefore, it's very important to purchase functional clothing which can shuttle through different situations. Do you know the usual functions of functional cloth, like waterproof and breathable, windproof & breathable, moisture-transferring, and quick drying, plus cool and dry fast? Do you understand those functions? Big brands roll out new fabrics with different prices and styles; there are all kinds of technical terms and data on tags confusing us. This article will explore the essence of waterproof & breathable fabrics, and the techniques of textiles coating, thus to know the meaning of functional clothing. Make you not only fashionable but also pick out proper products that meet your need.

(Photo resource: piqsels)

The Concept of Waterproof and Breathable

Waterproof & breathable textiles mainly apply for running, mountain climbing, and snow skiing. These textiles not only respond to the sport situation outfit needs against chilly, rain, snow, and gale but also keep clothing dry and comfortable. When you go shopping for outdoor functional clothing, you will know salesclerks introducing the feature of waterproofing and breathability. As its name implies, the textiles would be waterproof and breathable at the same time. We will explain with two parts, waterproof and breathability.

Waterproofness

The main function is to keep water out, for lightly waterproof as known as water repellent, will process on a textile surface with waterproof repellent. While the rain on the clothing surface, will form drops, it's easy to take off. If it rains heavily, water will infiltrate into a waterproof layer. When we paint or paste a membrane on the clothing's inner layer, the layer can resist liquid. The membrane is a special lateral 3D structure; the air penetration is half of the original synthetic fibers or down jacket, so it could be windproof.

Breathability

When human bodies sweat, the wet will volatilize into the atmosphere through fabrics, to deep clothing dry inside, and lower the temperature. The feature of waterproof breathability is to resist the rain outside, meanwhile discharge the wet, preventing condensation from humidity.

Waterproof and Breathability or Moisture Permeability

There are several functional jackets in the clothing market, and every brand's functional fabrics are various. Compared to moisture permeability and waterproof breathable, moisture permeability is to release sweat when the body is exercising. Breathability includes wet, air, and CO2. The original clothing emphasizes breathable function, letting the steam when bodies move gives off outside to keep comfortable and dry.

Waterproof Breathable texture structure

Waterproof & breathable textile is combined with a waterproof breathable layer and clothing surface or inner side. It matters a lot to combine waterproof breathable layers and textiles. There are three ways to process textiles equipped with waterproof breathable functions, including textile coating, laminating, and high-density weave. The waterproof breathable coating is to spray PU on the textile evenly; the waterproof breathable layer is to laminate the functional membrane on the textiles, and the high-density weave is to shrink weave structure pores as possible, then process with water repellent and tamping. It's a physical property of water to meet the waterproof need. Coating and laminating can achieve highly waterproof breathability, and provide different levels of waterproofing and breathability depending on diverse fields and functional needs, like flame retardant. Famous brands mostly use those two waterproof breathable textures. The membrane layer structure is the key factor of texture breathability and waterproofness, there are hydrophilic non-porous membranes and microporous membranes, which we will explain as follows:

Hydrophilic Non-porous Membrane

Make good use of hydrophilic ether functional groups to absorb moisture, spread, and exhaust wet, moreover make the wet give off to the atmosphere, due to the membrane aperture being very small(< 0.001 μm), so it can be proven against water. The processing applies to coating or transferring laminating forms into hydrophilic non-porous membrane textiles. The breathability may be worse than a microporous membrane, but it's better for waterproof and washable resistance.

Microporous Membrane

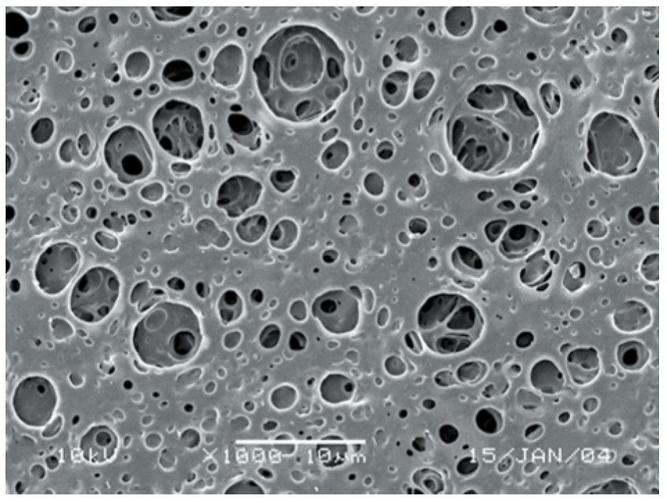

- Polyurethane

Apply polyurethane to the textiles' surface and put it into a coagulation sink, make good use of concentration and temperature difference between water and solvent to meet the balance, this process is called Le Chatelier's Principle.

In the exchange process, the membrane will become solid, and form the pathway from pore to pore. The aperture is 0.5 ~ 10 μm against the rain (100 ~ 6000 μm), and the wet which in our body is 0.0004 μm, can go through those microporous pores, to be waterproof and breathable. Besides, to prevent water drops soak into the clothing's inner because of capillarity, it will usually process waterproof coating on the textile surface.

In the exchange process, the membrane will become solid, and form the pathway from pore to pore. The aperture is 0.5 ~ 10 μm against the rain (100 ~ 6000 μm), and the wet which in our body is 0.0004 μm, can go through those microporous pores, to be waterproof and breathable. Besides, to prevent water drops soak into the clothing's inner because of capillarity, it will usually process waterproof coating on the textile surface.

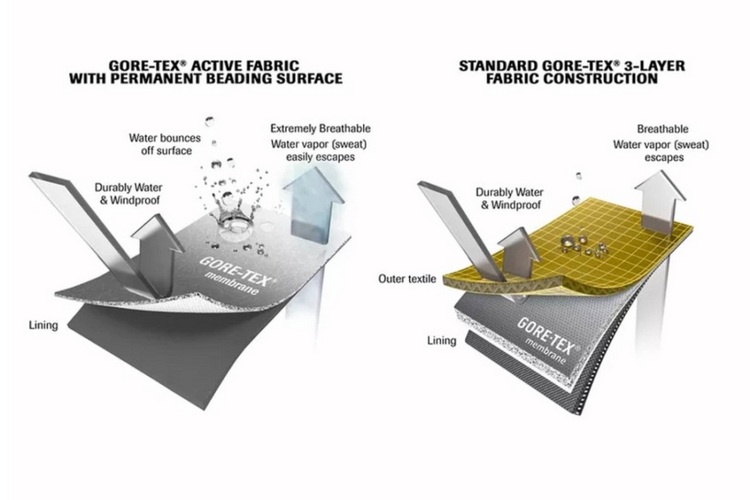

- PTFE Membrane Laminating

It's very famous and known as Gore-Tex, under certain conditions to heat the PTFE membrane, by stretching the membrane into porosity texture, there are 1.4 billion tiny pores per square cm, and the aperture is about 0.2 μm, so the breathability is very good. The outermost layer is processed by water repellent, laminate PTFE membrane under the textile. To prevent human oil-stuck pores, it adds another PU membrane, making the innermost layer have a soft lining.

The textile structure of Gore-Tex(Photo resource:GRAILED)

High-density Weave waterproof

Apply for diverse formula water repellent and tight grain structures; it depends on the waterproof demand of different brands(adjust the volume of yarn while weaving, change count of yarn), to make textiles waterproof. More, the gaps of warp and weft in the organization are bigger than steams, so steams can go through and make high-density weave breathable.

The Test Method of Waterproof Breathability

A jacket that is waterproof and breathable, the property depends on four factors, they are the water-repellent tablecloth, the water-proof membrane, the breathability, and the waterproof ability of the suture. The standard test methods that the industry uses are ASTM of American gauge, the JIS of Japanese standard, the International Standard ISO, or British BS. The test methods are as below:

| Test content | unit | Explanation | Global standard |

| Hydrostatic Pressure | mmH2O | The water pressure that per unit area can resist. | JIS L1092 ISO 811 |

| Water repellency | Rate 1 ~ 5 | To spread water on test cloth sample, and observe the moisture grade, grade 5 is excellent. | AATCC 22 |

| Breathability | g/m2‧24hrs | Under certain temperature and moisture, measure total volume of moisture goes through regular area at fixed time. | ASTM E96 JIS L1099 |

The guide to waterproof & breathable textile coating layer

Coating P Materials 'profession is to produce textiles coating layer materials, we roll out Hydrophilic Non-porous Membranes only for waterproof breathable base layer coating, face glue series( NC-5001, NC-5039E), it requires high breathability, high water pressure resistance, abrasion resistance, and good softness. If NC-5001 and NC-5039E are combined, they correspond to environmental law, and the demand of consumers' need for function and comfort, furthermore, many famous brands adopt them. We could provide diverse customer-made formulas and R&D service, and continue rolling out high add-valued eco-friendly materials. If you want to know more product information, welcome to contact us.

| Product | NC-5001 | NC-5039E |

| Type | for Base Layer Coating | for Top Layer Coating |

| Adhesive | Hydrophilic Two-Component Type with PU | Hydrophilic One-Component type with PU |

| Suit for membrane structure | Hydrophilic Non-porous Membrane | Hydrophilic Non-porous Membrane |

| Process | Coating process | Coating process |

| Product Feature | ◆ high breathability、high water pressure resistance、abrasion resistance, and good hand feel ◆ breathable meets all kinds of famous brands need |

◆ high breathability、high water pressure resistance、abrasion resistance, and good hand feel ◆ breathable meets all kinds of famous brands need |

| Product Application | Waterproof breathable textile | Waterproof breathable textile |

References:

- FIBRES & TEXTILES in Eastern Europe January / December 2005, Vol. 13, No. 6 (54).

- https://www.grailed.com/drycleanonly/gore-tex-history

- https://blog.xuite.net/ncku_ob_blog/twblog/140338680