Enterprises have invested in the circular economy to accelerate the development of bio materials.

The issue that the globe keeps discussing over decades, Greenhouse effect, has stepped into new era in this century. In addition to trying to awaken consumers’ environmental awareness through marketing reports, brand enterprises have also invested in circular economy and played pioneering roles. They have started to reduce plastic production from the manufacturing side, and advocate how low-carbon products can be integrated into our lives. It is expected that the reduction of industrial emissions will slow down the drastic climate change and bring solutions to the gradually consumed oil reserves. When Covid-19 outbreaks all over the world in early 2020, the environmental awareness and plastic reduction step back because of the protecting methods to keep social distancing. Since it is unavoidable to use disposable tableware and containers, at least we can choose the materials which conform to the concept of recyclable, renewable, and decomposable in the industrial cycle as much as possible. From the perspective of an enterprise, using biomass substrates as raw materials can not only reduce waste accumulation and pollution treatment, but also continue to be recycled after recycling and decomposition to achieve a pragmatic circular economy. However, from the perspective of end consumers, the only way to reduce the demand of the petrochemical industry is to implement plastic reduction from daily basis.

Petrochemicals are chemical raw materials and fuels extracted from petroleum and used in industry, agriculture or daily life. Petrochemicals have dominated most of the market demand over the past few hundred years, and petrochemical plastics have indeed brought huge business opportunities in various industries and made live become convenient. In fact, 99% of the plastic originates from oil or natural gas and cannot be decomposed by natural microorganisms. From the stage of manufacture, usage, to disposal, each of it will not only pollute the ocean, increase greenhouse gas emissions, but also continuously accumulate and release toxic substances, causing harm to human body and the environment. We can even foresee what kind of polluted environment the next generation will live in. Therefore, environmental protection scholars and scientists all over the world advocate to actively developing the circular economy model, and striving for more time for the earth to repair itself.

(Photo source: Official Website of the European Parliament)

According to research, at least 8 million tons of waste plastic flow into the global seas every year, and plastics account for 72% of the total amount of marine debris. The World Economic Forum and Ellen MacArthur Foundation have jointly issued a warning that by 2050 the weight of waste plastic in the global ocean will be more than that of fish in the water! According to the report of the United Nations Environment Programme (UNEP) and Plastic Disclosure Project (PDP), the plastic waste at least has caused $13 billion dollars loss in terms of the marine ecosystem every year, which has become the second largest threat to the earth's ecology following climate change.

Because of its cheapness, light weight and durability, plastics appear in every corner of our daily lives. Among them, the most commonly used is for packaging, accounting for about 26% of the overall plastics industry. It is also the largest application of the plastic industry in the world. In 2013, the global use of plastic packaging on the market was about 78 million tons. According to the trend, the output of plastic packaging is expected to increase to 318 million tons by 2050.

Development status and future trend of biomaterials

The International Energy Agency (IEA) initiated Bioenergy Task 42 in 2007 and defined biomass as sustainable production technology for the energy and products. By using the harmless, environmentally friendly, and Biorefinery technology, the biomass is transformed to replace the raw materials extracted from petroleum. This gives full play to the economic value of recycling, lessens the dependence on petrochemical raw materials, and results in improvement to the earth's environment. In short, petrochemical refining is petrochemical, biomass refining is agricultural chemical.

In order to solve the problem of the proliferation of traditional plastic waste, many countries have taken the advantage of biodegradable properties of bio plastics to research and develop over years. In the early stage of production, the performance and cost recovery rate of bio plastics are not as fast as those of traditional petrochemical plastics, resulting in the limitation of application fields. Facing the current ecological crisis, countries have to legislate to drive enterprises to actively respond to the development of bio plastic applications. In the early stage of development, the "biological hybrid method" was the first to enter the market, that is, to mix some biomass materials with petrochemical raw materials. It not only has the concept of circular economy and low-carbon benefits, but also has the same performance as traditional plastics. This becomes a compromise between market demand and environmental protection. The 30% Bio-PET beverage bottle produced by Coca-Cola is representative of this development project.

At present, the global biomaterials are mainly developed in Europe, America and Japan; the market applications of biomaterials in Europe and America focus on compostable bags, food packaging materials and disposable polymer products, while Japan has invested heavily in biomaterials in automobiles and 3C electronics products. It is undeniable that biomaterials have gradually been designated for use by brand manufacturers. Only by actively cooperating with polymer processors to develop related products and introduce the concept of circular economy, and deploy the traditional petrochemical industry transformation and upgrading strategy, can it truly catch up with the high-speed train of sustainable development.

Sugar PE?! The plastics planted can be 100% recycled, regenerated to reduce 35% carbon emissions.

A well-known beverage packaging brand, "Swedish Tetra Pak", launched a beverage open lid made from sugar cane containing high density polyethylene (HDPE) in 2011, and became the first supplier that use bio plastics in liquid food packaging the same year. Tetra Pak Packaging has made excellent progress in the application of biomaterials every year. The most representative of which is Tetra Pak’s paper and bio-based PE, all from Bonsucro sustained verification of sugarcane certified by FSC™ in Brazil, and its carbon dioxide emission is less 35% than any other same box sold in the market. Moreover, the source of environmentally friendly materials can be traced back and achieve the goal of circular economy of "endless raw materials, zero waste and renewable".

(Photo source: Bonsucro official website)

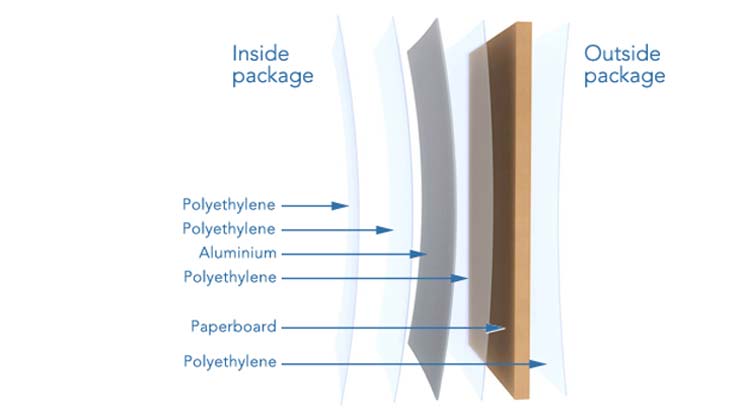

To ensure the freshness of contents in the package, each Tetra Pak carton package contains a recyclable polymer plastic film. This plastic film can be reused in the recycling plant through the "paper-plastic separation" technology of hydro-dispersal pulp to achieve the environmental goal of 100% recycling. However, the conversion polymer industry is still in its infancy, and there is still a long way to go before renewable polymers can completely replace traditional petrochemical polymers.

(Photo source: Tetra Pak official website)

In 2015, the Just Water sold by the second-generation American star Jaden Smith and his father is filled in sterile tetra top carton instead of regular bottles. Since more than 80% of the packaging materials are from sugar cane, the paper is light and the transportation process does not require refrigeration, the carbon footprint is reduced by 74% compared to ordinary PET bottled water. This is killing two birds with one stone because it can reduce the waste as well as carbon. Taiwan Yimei Foods Co., Ltd. also took the lead in Asia and launch dairy products packed in "Tetra Rex" all-plant cartons in 2019. This is 100% free of petrochemical and known as "all-plant cartons that can be grown."

(Photo source: JUST Water official website)

(Photo source: Yimei "Tetra Rex")

Tetra Pak is an indicator enterprise for the implementation of circular economy. It not only actively develops bio materials and bio energy, but also cooperates with downstream brands to capture more and larger beverage markets without changing the existing recognition of classification and recycling, and continues to lead consumers to practice and realize a sustainable environment.

Further reading: Application and production process of paper-plastic lamination material in daily life

Circular economy will become the main production mode of international enterprises

In recent years, the pollution of the ecological environment and climate change has been raging, and the development of bio plastics has become an inevitable trend. Food packaging is the largest application field of bio plastics. At this stage, it is widely used in various rigid and flexible packaging products, including biodegradable, compostable and bio-based packaging.

Circular economy is not just an issue. In practice, it’s necessary to implement systematical cooperation through region, improve the allocation of resource, and enhance the utilization of resources so that the input and emission can be reduced during the production process and create higher value by cost-saving concept. Compared with linear economy, circular economy is the core issue that we need to actively explore and propose solutions to solve it. It has become a new trend of corporate profitability in the 21st century. It is expected that in the near future, circular economy will become the main production mode of international enterprises. According to estimates by McKinsey Consulting, if the economic development mode moves towards resource recycling in an all-round way, it can save up to $630 billion of material cost every year, and create economic benefits of up to 1.8 trillion euros a year by 2030.

References:

-

Gina-Marie Cheeseman, Shifting Plastics to a Circular Economy Could Generate Billions, (2016).

-

Lin Xijin, Analysis of Bio-refining Industry in Circular Economy, (2017).

-

Chen Jianming/ Liu Rongchang, Petrochemical Industry in transformation: Bio material industry replacing petroleum source, Science Development No.531, (2017.03).

-

CTCI Foundation, Resource and product recycling application technology, Book III of the Circular Economy Series p.16-17, (2018)

-

Materialsnet, Biological cycle and next generation bio polyester materials, (2019)

-

Taiwan Circular Economy Network

-

Huang Yuzheng, Circular Economy, The key to Taiwan's path to sustainability, (2018).

-

Tetra Pak, Sustainability Action 2019 Sustainability Report, (2019).